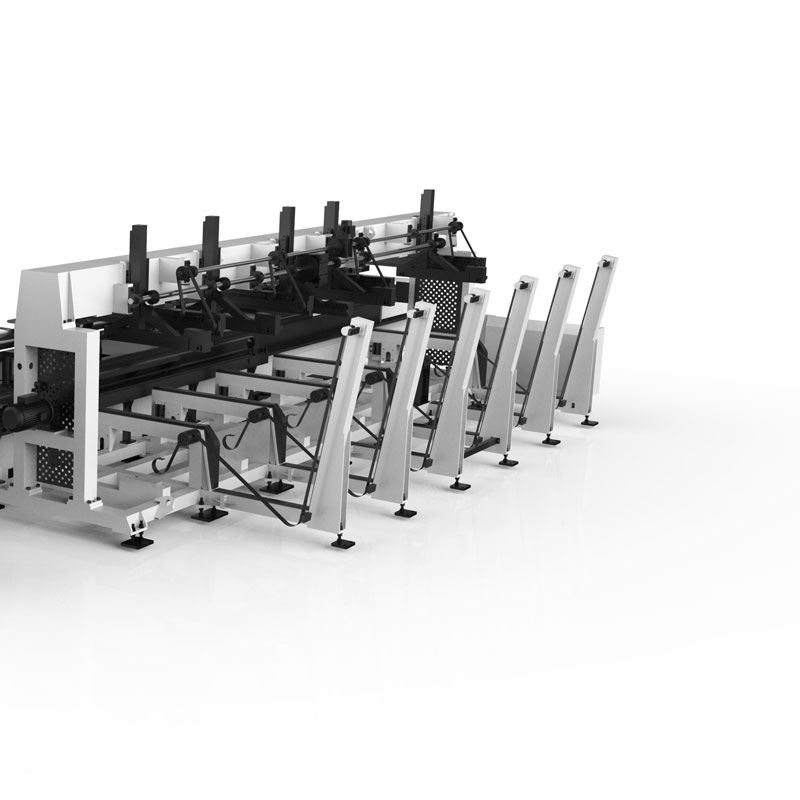

The finished product is automatically dropped to the storage bin.Easy loading of pipes of different sizes, lengths and shapes.

The finished product is automatically dropped to the storage bin.Easy loading of pipes of different sizes, lengths and shapes. With "general ',' intelligent '," efficient' and 'humanized " as the key words, they can accurately meet customer processing needs and use habits, and help customers to achieve fast, batch and low-cost production and processing.Equipped with special cutting sleeve software, simple operation, high precision, strong professional, widely used in kitchen and bathroom, fitness equipment, storage shelves, sun tent umbrella, auto accessories, etc.

The function of intelligent automatic pipe cutting machine is more comprehensive: intelligent automatic pipe cutting machine through the CNC intelligent control system to the pipe feeding, feeding, cutting and tail material processing to achieve intelligent, automation.No dedicated person is required to operate the machine.Traditional pipe cutting machine mainly relies on manual operation, during the cutting process, people can not leave the machine.

Continuous processing, after the processing of the previous tube, the machine loads the next tube in time to ensure that only one tube is fed to the conveying arm at a time, making production more efficient.