Fiber laser cutting machine is mainly used to cut carbon steel, stainless steel, copper, aluminum and other metal materials. It can meet the cutting processing needs of most industries. Because of the small laser spot, high energy density and fast cutting speed, laser cutting can obtain better cutting quality compared with traditional plasma, water jet and flame cutting. At present, laser cutting machine has been widely used in advertising signs, sheet metal processing, solar energy, kitchenware, hardware products, automotive, electrical appliances, precision parts and other industries.

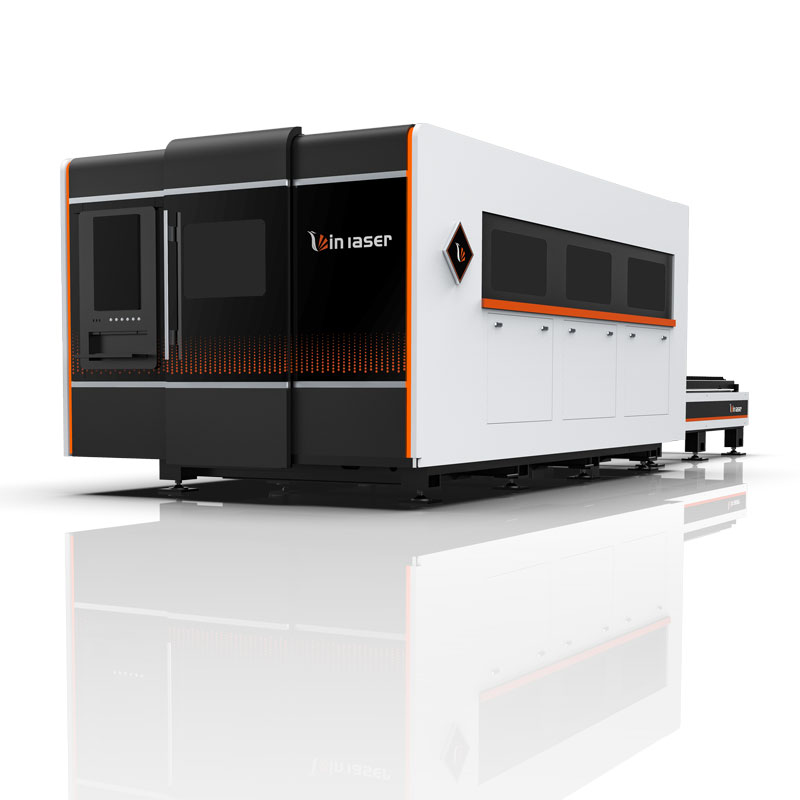

Double platform exchange type design, the pulley is closely fitted with the track, and the built-in pulley runs smoothly and the transmission mode is stable and reliable, shorten the standby time and improve the working efficiency.

Without Manual Focusing

The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting.

Bigger Adjustment Range

Adjustment range -10 mm~ +10mm, precision 0.01mm, suitable for 0 ~ 20mm different types of plates.

Long Service Life

Collimator lens and focus lens both have water-cooling heat sink which reduces the temperature of the cutting head to improve the life of the cutting head

Fully enclosed protection design, intimate care of the operator’s health. Automatic collection of smoke and dust, it’s non-polluting and environmentally friendly.The electric cabinet is integrated with the body, and the area is smaller.Therefore, this fully sealed structure and standard wire can prevent dust from entering and dangerous flame.

During the processing, each blind spot area can be monitored at any time, and the cutting process can be controlled; the high-definition intelligent monitoring system, remote alarm operation is no danger.